Protecting Your Transom

Securing The Boat To The

Trailer

Tire Maintenence

Trailer Tongue

Wheel Chocks

Saving Your Trailer Lights 4/6/18

Safe

Transportation of Accessories

Steering System Problems

4/7/18

Protecting Your

Transom

The transom is one of the parts of the boat which handles a great deal

of stress and force. Not only does it support the weight of the

motor, but it also withstands the application of thrust from the

motor. Generally transoms are reinforced with heavier duty

material and some sort of brace. So you will see the normal hull

backed with heavier metal or 1.5" wood.

Now when the motor is too heavy, or rather, the transom is not

supported properly during transport of the boat, extra stress is put on

the structure(s) and can lead to damage. The first picture shows

a transom brace that has been partially broken. You can see about

an inch or so tear in the metal brace near the top, this is where the

transom was flexing away due to the weight of the motor bouncing as the

trailer went down the road. The damage occured as a result of a

motor being transported a long distance without being supported.

The 130lbs or so of weight caused flex on the transom and this stress

eventually caused the aluminum to break. Metal fatigues when

flexed repeatedly and eventually tears/breaks. Aluminum isn't

exactly the strongest metal when in a thin guage.

The 2nd picture shows a backer board of a transom that did not have a

metal plate placed on between the stern clamps and wood. Keep in

mind that wood is a sponge, so during the normal condensation cycle

each day, or even if it rains or you happen to have a spell of dry

weather, the clamps can loosen up. Well if you keep tightening

these bunny ears down, you just keep compressing the board and in fact

weaken it in these areas. There should be an aluminum plate (or

stainless steel) so that the compressive forces of the stern clamps are

distributed over a wider area.

A simple way to help prevent these issues is by installing a transom

brace or "transom saver" on your trailers aft frame. What this

does is accomplish two things. It raises the motor off the ground

so that you have more clearance between the skeg and the ground, and

secondly it pretty much stops the flex of the transom as you drive down

the road. It should be noted that if you have powertrim, using

your trim unit as a support DOES NOT stop stress on the transom and you

may very well just accomplish ruining your expensive trim unit by

transporting the motor in a tilted position, supported only by the

hydraulic unit. Transom supports are available at your local

Wally-world or sporting good store, and cost about $35.00. An

inexpensive, no-brainer investment that will last for years,

compared to the cost of fixing your motor and transom of your boat.

Securing The Boat

To The Transom

One of the most common things I see when doing motor installations are

vessels which are loosely secured to the trailers that they sit

on. The obvious issue here is you don't want to lose your boat

off the trailer during transport. Yet people think that the bow

winch is enough to keep the boat where it sits, or that the bunks alone

(regardless of if they are simply wood bunks covered in fabric or

the roller type) are enough to keep the boat in place.

These are big mistakes. People rarely consider what would happen

if they had to make a sudden braking, acceleration, or aggressive

swerve due to another motorist. It doesn't take much to throw a

boat off a trailer when it's secured in a questionable manner, and even

when you take extra measures to protect your boat, that doesn't

guarantee protection against a rollover.

One thing is for sure, ignorance is not bliss, and a loose boat puts

you, your passengers, and other motorists at extreme risk for injury or

even loss of life if you don't secure your boat properly. You

also assume quite a bit more liability and risk for lawsuit should you

be found at fault for not taking the time to be informed.

At a minimum, your boat should have a good quality bow winch. The

one pictured below has expired. The winch should have a strap,

not hardware store line, and should be free of significant rust.

Check the function of the winch locking mechanism. It should have

a strong 'click spring' to insure the boat doesn't become loose.

A marginal winch could get loose as you're driving down the road and

hit a bump, jarring the locking mechanism out of place and now all that

keeps the boat in place is gravity. A sudden acceleration and the

boat falls off the back of the trailer.

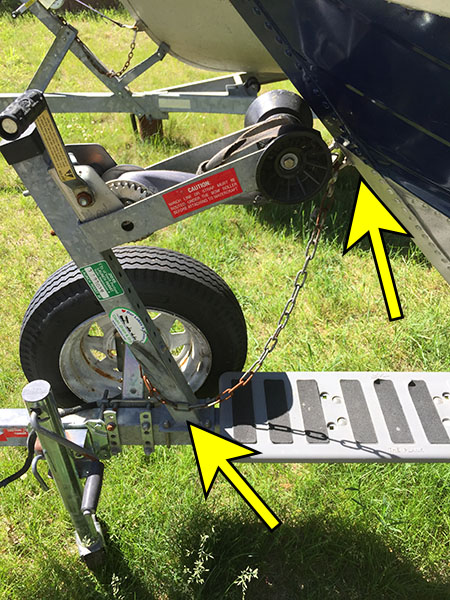

The 2nd picture shows a bow safety chain as a backup measure.

This provides a 2nd layer of protection should the bow winch suddenly

let loose. Now imagine you are launching or trailering your boat

on a ramp and the winch lets go. Your boat slides off the back

of the trailer and lands on your motor skeg with the full weight of the

boat along with momentum of the boat sliding backwards. Or say

you or a friend is standing behind the boat. That person is

crushed and

possibly dies. Does it make sense to have a safety chain at

your bow?

Additional straps

should be used to further secure the vessel to the trailer. A mid

hull strap, such as a simple ratchet strap, helps keep the boat

'seated' on the trailer so it's not bouncing all over the place.

It also discourages a roll-off situation if you swerve your car

suddenly to avoid, say, another car, a deer, a pedestrian.

Transom straps also discourage the boat from sliding backward (2nd

picture below).

Keep in mind that ratcheting straps should be used, and depending on

the size and weight of your vessel, pick up straps that can handle a

load. Generally the wider the strap, the more stress it can

handle. Don't sacrifice your safety or the security of your rig

over skimping on a $10 strap. Paying a little extra is far worth

the investment to say the disastrous alternative. If

your ratchet strap is getting tired/rusty/fatigued, go out and buy

replacements. You can always hit them with blaster or WD-40 to

help keep them loose and easy to operate. When they get dry or

corroded they are miserable to deal with.

Tension straps (the type that

have a 'claw' rather than a ratcheting mechanism, and rely on you

simply 'pulling hard' on it) should be avoided. These types of

straps simply don't give you the leverage to really tie things down.

Tire Maintenence

The common sense approach is to monitor your tires regularly. The

same things you do for your car tires applies for trailer tires.

What people tend to forget is that trailer tires simply don't last as

long as automobile counterparts. The reason behind this is

because they

generally are smaller in diameter. So they are turning much

higher RPMs for any given speed that a larger tire rotates. This

accelerates wear & tear.

In many instances trailer tires sit parked in the same spot for months

or years and are used rarely. Now they may not have a lot of road

miles on them, but letting rubber sit in the same spot for extended

periods leads to dry rot, and a permanent form. In the

off-season, you should jack your trailer up off the ground and support

the weight of the boat and trailer using the trailer frame, say,

resting on cement blocks. This

saves your springs and tires from having a constant load applied

to

them in one specific spot, and will greatly extend the life of your

rig. This may take

you a half hour, but is the correct way to put things away.

Check your tires regularly for the following things: tire

pressure (check the rating on the tire itself), tread, shape (round not

oval from sitting), and dry rot. The picture below shows an

expired tire with dry rot. If you've ever had a tire blow out on

you during a trip or suddenly deflate, you know risking a fun trip over

replacing a potentially questionable tire makes no sense. If you

haven't

experienced this yet,

don't push your

luck. Use the analogy many

people use when considering whether to save or throw out an old

vegetable: "When it doubt, throw it out."

While not directly related to tires, maintaining your axle and bearings

is a must as well. Spend $30.00 and buy a pair of bearing buddies

(pictured). What these do is attach in place of the normal axle

hub caps. They are spring loaded and have a grease fitting for

your grease gun. So you fill them, and the springs

force the grease into the bearings as the grease slowly burns off

during normal use. They are much less messy than hand-packing

your hubs too.

Trailer Tongues

Many times, I work on rigs that have been sitting for a long time in

someone's back yard. The boat is usually not the issue, it's

generally the motor that is being replaced but the trailer may

still have a lot of the original components. The tongue of

the trailer HAS to be in very good shape. If it is at all

'marginal' or in question, it should be replaced. The pictures

below show the difference between an old, expired tongue and a new

one. You can see the corrosion throughout the older tongue, with

badly corroded hitch chains and open hooks. Color doesn't mean

much, it's how pervasive the and how long it's been exposed to elements.

What you don't see in the picture is the original tongue lock

pin. This was a rusted old clevis pin that if bent slightly would

have snapped in half. Keep in mind for safety, the tongue has a

locking mechanism with a pin that should prevent the lock from ever

opening, allowing a trailer to jump off of the towing hitch. Now

if this were to happen, the two chains leading from the trailer and

attaching to your towing package is the last backup to keep the trailer

from being completely lost from the back of a vehicle.

I have seen trailers that have a single rope tied to the rear of a

customer's car, or even no backup chains at all. The picture on

the left is a low-quality, dated system with open hooks. Well

all it takes is just the right type of bump or bounce and these

chains can fall off. Or if you have a tongue lock which is very

rigid, corroded, or simply expired and not functioning at all, you are

depending on

GRAVITY to hold

your trailer from falling off of your ball

hitch. Not the type of gamble you want to fool with!

The picture on the right shows the new tongue with locking safety

hooks, and a large, new clevis pin. A trailer tongue costs only

about $25.00 and can be replaced by removing the lag bolts which hold

it in place. Loosing your rig, you might as well multiply that

simple replacement cost x100 (literally) if the plaintiff is mildly

motivated.

Wheel Chocks

A must have in general. These prevent the trailer from rolling

away. So if you go on a trip and need to leave your trailer

behind, you can park it in a spot at your hotel and keep it from

rolling away accidentally. They are pretty inexpensive, usually

not more than $15 for a pair. On the note of traveling, buy a

trailer hitch safety lock from your local hardware store. This

significantly discourages theft.

Saving Your

Trailer Lights

If you've ever been ready to go on a trip only to realize that your

trailer lights are malfunctioning, you know it's a real headache

figuring out what's wrong with the wiring. Well the

lighting circuit isn't all that complicated (generally a green/brown

and yellow/brown combo). However tracing the root of the problem

can be an exercise in frustration if you have a converter box on your

vehicle, or simply don't know your way around a multimeter. What

makes it even more fun is having to walk back and forth between your

drivers seat and the back of the trailer to see which functions are

working and which aren't. Wedging a 2 x 4 onto your brake pedal

is what most folks do during this process.

Generally, the root of most issues is going to be corrosion between

connections, bad grounds, or a blown lamp. Now the first two

issues

you can never really fully stop or prevent, but you can discourage

corrosion between connections by making better connections than what

your trailer light kit probably set you up with. First off, don't

use wire nuts or quick connectors that usually come with most

kits.

What you should use is heat shrink type wire splice connectors.

You

splice two wires together, crimp the connector, than use a simple heat

source (you can even use a lighter if that's all you have) to shrink

the connector, effectively sealing off the spliced wires from moisture.

When you go to back your trailer into water during a launch or out

while trailering, disconnect your wiring harness. You should do

this when you turn off your vehicle to load up gear, prior to backing

into the water. This gives your trailer lamps a few minutes to

cool off. What happens when you take a hot glass and dunk it in

cold water? It shatters. Same thing happens with your

trailer lights. Even if your light kit says "submersible," those

bulbs will still explode if they're on and hot when you back them under

water. The important aspect of this advice is to disconnect when

launching. Leave it unplugged after launching, dropping off the

vehicle/trailer, and it will still be cold when you go to

trailer. By the time you have unloaded your gear and prepped your

rig (after a day, or few days, of being on the water), the lights and

wiring should be dry enough to be plugged back in for the journey home.

If you launch/trailer in salt water, just plan to replace your

bulbs/wires with no rhyme or reason. Best practices help decrease

this hassle, but salt crytals are interesting chemical reactions, to

say the least. Below is a picture of a trailer lamp terminal

corroded from salt. This actually only takes a single exposure to salt

water to start. Usually after 3 times submersed (even with the

'submersible kits'), the lamp may stop working due to salt corrosion.

Your ground lead off the wiring harness (usually connected at the

tongue) should be attached to the trailer frame and prior to attaching

it, thoroughly clean that part of the trailer frame with a heavy grit

sand paper until you see shiny metal. Once attached, use a black

neoprene dip or liquid tape to seal it off from exposure to the

elements. This will again discourage corrosion from screwing up

the ground circuit of your light system.

Remember

that your trailer hitch is actually the ground to the negative side of

your trailer light system. SO, if you see your trailer lights

flickering on and off with no boat on the trailer, it's probably

because your trailer is aft-heavy, and the hitch isn't completely

seated on the ball. NO GROUND = NO CURRENT FLOW = erratic trailer

light behavior.

Safe Transportation of

Accessories

How many times have you been driving down the highway to your local

waterway and saw one of those bright orange life jackets on the

shoulder? The highway department must have an entire storage unit

full of these. Even though a life jacket may seem harmless to fly

out of the boat, consider what else could come out of your boat if you

break heavily or swirve suddenly.

Batteries, anchors, tackle boxes, coolers, gas cans, spare tires, oars;

these all become grenades if you launch them. There is a reason

why there are safety belts in your car. You slam on the brakes or

hit something, you keep moving even though the car stops! The

same goes for everything else that ISN'T strapped down. Make sure

you place loose objects in a trunk or storage box, or insure they are

securely strapped down. DON'T put gas cans in your trunk for

obvious reasons. The battery pictures below is not secured

adequately, utilizing a strap that is knotted. Obviously the

spare tire and paddle are not going to stay inside the boat if any

aggressive evasive maneuver is made with the towing vehicle.

Steering System

Problems

Many times I do outboard installations, the owner wants me to update

their steering system from the older style pulley and wire rope style.

This is to the modern day style Seastar, single cable system that has a

worm gear which locks the boat into a single direction for hands free

steering at low speeds. The older style with pulleys even when new and

calibrated does not allow for this. Most boats will pull to the right

due to the natural spinning of the propeller when you let go of the

steering wheel at much above 1/2 throttle.

It

should be noted that the original style of steering with pulleys and

ropes was used for nearly half a century, but are long but obsolete,

with a discontinuation of this style since the late 1960's. So when

someone buys a classic fiberglass or aluminum boat that has the

original rigging, we are talking about 50+ year old components that are

long overdue to be replaced! Old motors can be updated to newer style

steering with a knowledgeable mechanic, and for relatively low cost in

most cases (usually <$450.00). Your life is worth $450.00!

When

the older style steering fails, the rope can break, but more commonly

it slips off the steering wheel hub or jambs on one of the pulleys

because of slop/slack in the line from stretched cables, springs, or

just general wear and tear. With something that is 50 years old this

happens more often than you might think. When you are moving along at

WOT and lose steering control of the boat it takes very little to be

thrown from the craft. In many instances the boat will start doing a

'circle of death' where it goes hard left or right, and you get run

over and chopped up by the prop. This happens about a dozen times a

year in New Hampshire (home state). There is nothing eerier than seeing

an unmanned boat circling around, with marine patrol waiting to see

when the engine will run out of fuel.

Below is a picture of a

boat brought in by a customer where his modern day seastar steering had

seized. Inspection of the cable did not reveal anything. Now these

units can get stuck if no maintained/greased down a couple of times a

season. The cable at the motor end will get stuck in the stern bracket.

You usually know this is starting to happen ahead of time because the

steering wheel will get stiff. In this instance, the hub itself was so

badly corroded that it seized up. With the bezel hiding the hub, you

would not have known this was the problem.

The boat was sitting on a mooring in a salt bay for all the warm months

of the year, and the owner knew very little about boats in general.

These fellas showed up to the shop with a small whaler they had

inherited, and it was sitting on a trailer with a broken axle with two

badly balded tires, which

they had driven 60 miles to deliver the boat on! Needless to say,

some

people should not be using boats, and should consider moving to Arizona

or some other desert climate where there are no boats.